Using liquid nitrogen or co2 to isolate the problem area in the pipeline by freezing the product inside the pipe to form one or more solid pipe freeze plugs.

Liquid nitrogen pipe freezing equipment.

Put simply pipefreezing is a non intrusive controlled method of providing pipeline isolation through the application of liquid nitrogen the pipework freezing process begins by drawing out the heat from the product within the pipe until it reaches a temperature below its freeze point until eventually the product freezes to form an internal ice plug.

Direct liquid nitrogen pipe freezing is the most common procedure used to establish isolation on a pressurised pipeline requiring the application of liquid nitrogen to the external surface of the pipe.

The qwik freezer kit is a more commercial grade co2 pipe freezing system that can freeze lines single or dual 3 8 1 1 2 through 3 8 to 8 00.

Hft pipestoppers accu freeze the controlled liquid nitrogen ln2 pipe freezing system is a method to freeze stationary liquids in a selected section of a pipe or tubing.

The standard accu freeze af1000 kit is used to create an in line ice plug capable of withstanding 2000 psi in pipes up to 12 inches in diameter.

The kit uses liquid carbon dioxide to create ice plugs in sections of pipes.

Jt equipment service brings today s latest technology we will freeze the piping using the patented accu freeze system the most advance pipe freezing system in the world.

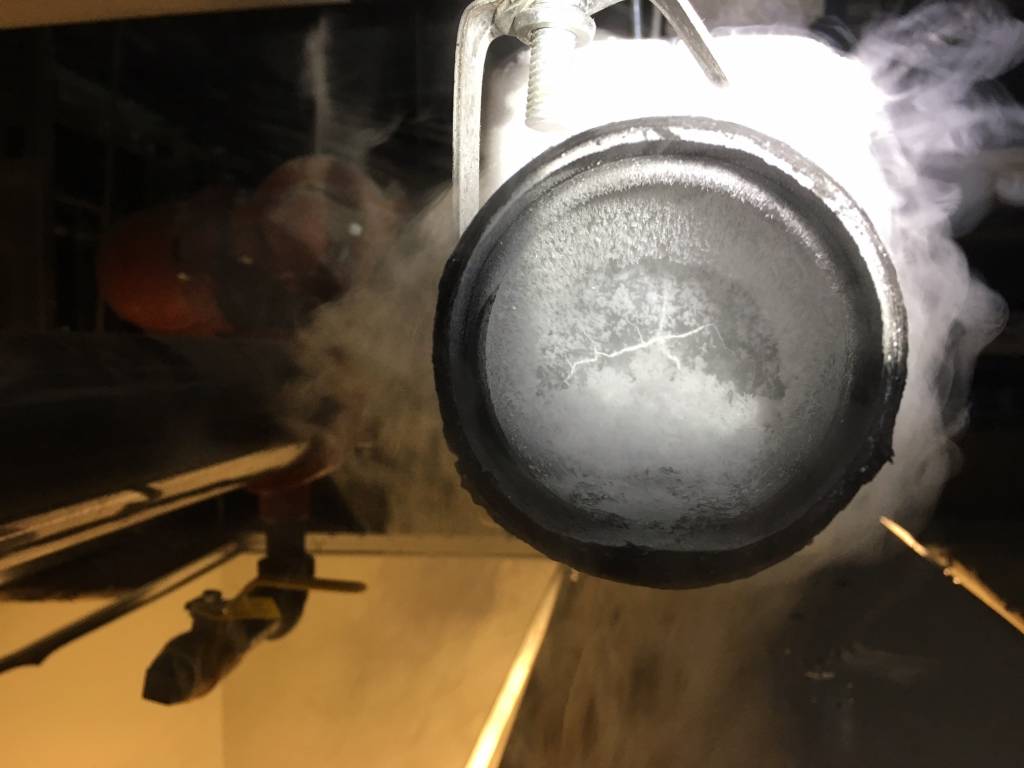

Figure 2 middle picture.

The arctic freeze kit can freeze lines from 1 4 to 2 00 through 1 4 to 6 00.

Pipe freeze services 1 2 36 pipe freezing is a non intrusive cost effective and quick method to perform pipeline modifications without draining the system.

Kits are supplied with three freezing jackets for pipes 4 13 77mm o d and two 20 hoses.

The pipe freezing kit eliminates the need to drain systems and shut down operating equipment when making pipe repairs.

When an ice plug is formed the necessary modifications are made.

This allows for very little drain down or refill having to bleed problematic air out of pipes during refills and in many cases no system downtime.

Figure 1 left picture liquid nitrogen is injected and the pipeline monitored.

It utilizes liquid nitrogen in a controlled and automated system to safely and reliably freeze static liquids in a selected section of pipe or tubing.

This transfers the low temperature liquid nitrogen through the pipe reducing the pipe fluid to a temperature below its freezing point and.

The freezing chamber is installed on the pipeline.

It is the world s only patented digitally controlled pipe freezing system thus allowing you to accurately and safety create an ice plug.

Using liquid nitrogen ift isolates your problem area in the pipeline or vessel by freezing the product inside the pipeline to form a solid plug.