Safe handling and use of liquid nitrogen characteristics of nitrogen 78 of atmosphere colorless odorless tasteless and nontoxic boils at 320 degrees fahrenheit 196 c non flammable will not support life gas is slightly lighter than air liquid nitrogen facts 1 cubic foot of liquid nitrogen will expand to 696 cubic feet of 100 gaseous nitrogen at 70 f the nitrogen gas can displace the.

Liquid nitrogen tank venting.

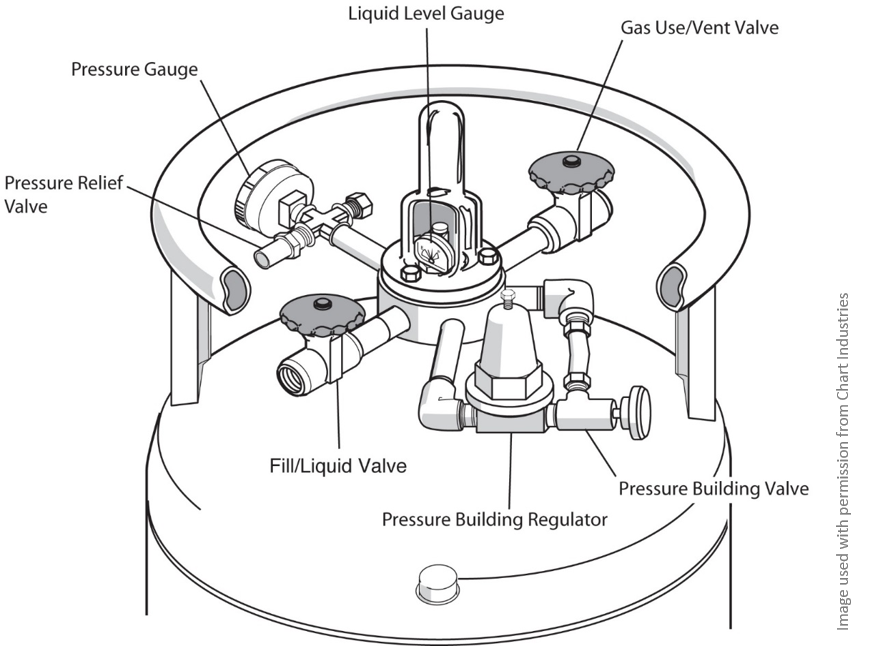

Then open the liquid use valve to allow head pressure in the tank head to force liquid up to withdrawal tube and out the liquid use valve.

We would like to show you a description here but the site won t allow us.

Api rp 2521 use of pressure vacuum vent valves for atmospheric loss first edition 1966.

Use cryogenic liquids only in well ventilated areas or with local exhaust ventilation.

Nonrefrigerated and refrigerated 1998.

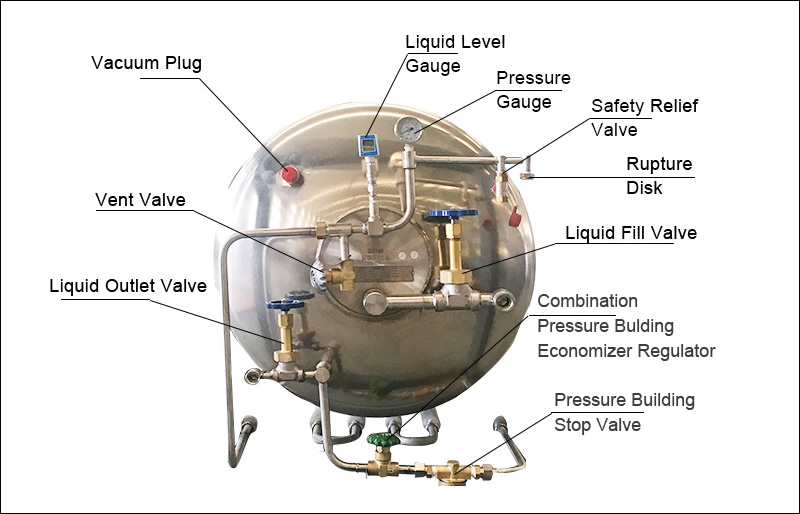

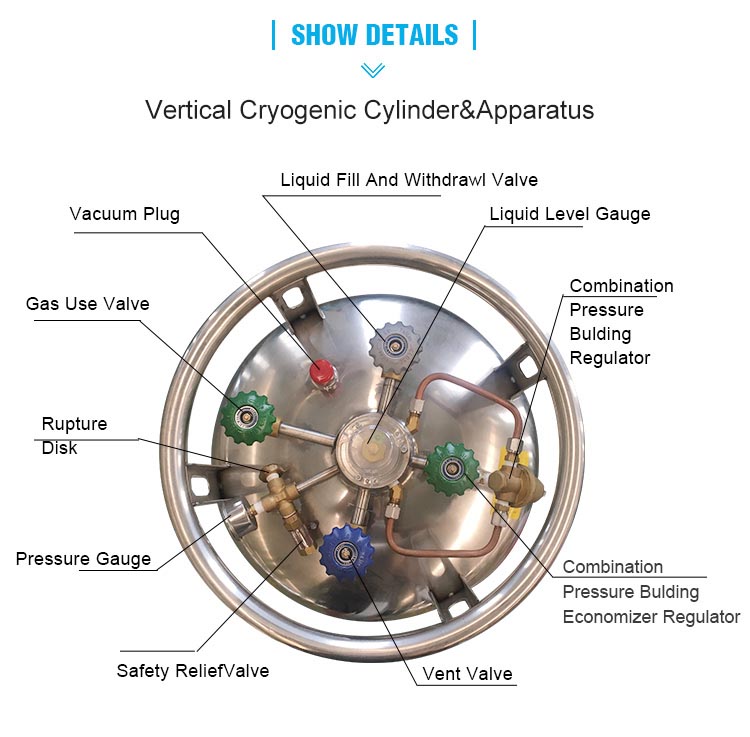

Ensure all safety valves and vent valves are unobstructed and functioning properly.

Api std 2000 venting atmospheric and low pressure storage tanks.

Check the safety vents on liquid nitrogen tanks at least twice a week.

When ln2 boils it produces gaseous nitrogen which displaces oxygen from the air.

Never pour cryogenic liquids into any drain.

Hence if sufficient liquid nitrogen is vaporized so as to reduce the oxygen percentage to below 19 5 there is a risk of oxygen deficiency which may cause unconsciousness.

Hazards associated with liquid nitrogen asphyxiation.

Transport the large low pressure liquid nitrogen cylinders used on campus are equipped with wheels and.

This results in an oxygen deficient atmosphere particularly if vented into a closed space and asphyxia can result.

Cold rooms are poorly ventilated small rooms and must not be used for the storage of liquid nitrogen vessels.

Liquid withdrawal should be done at low pressure to prevent flash losses.

1990 specification for bursting discs and bursting disc devices british standards institution.

Pressure may build up in liquid nitrogen storage cylinders.

While still allowing for venting of the ln 2 gas.

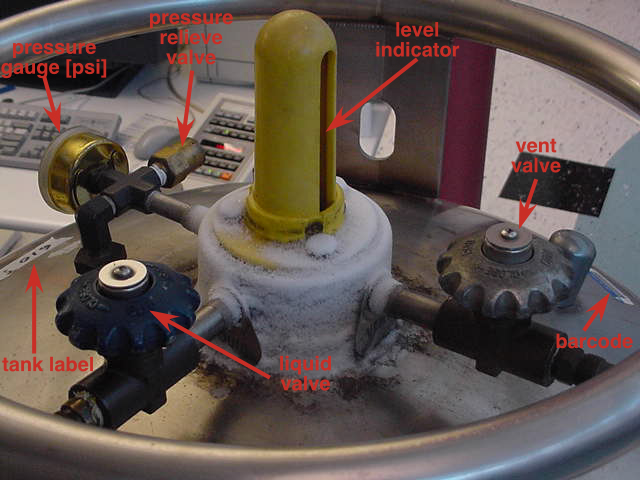

In addition to these four circuits there is also a vent valve on the top of the tank that gives the end user or supplier the ability to vent the head pressure off of the tank for service or filling.